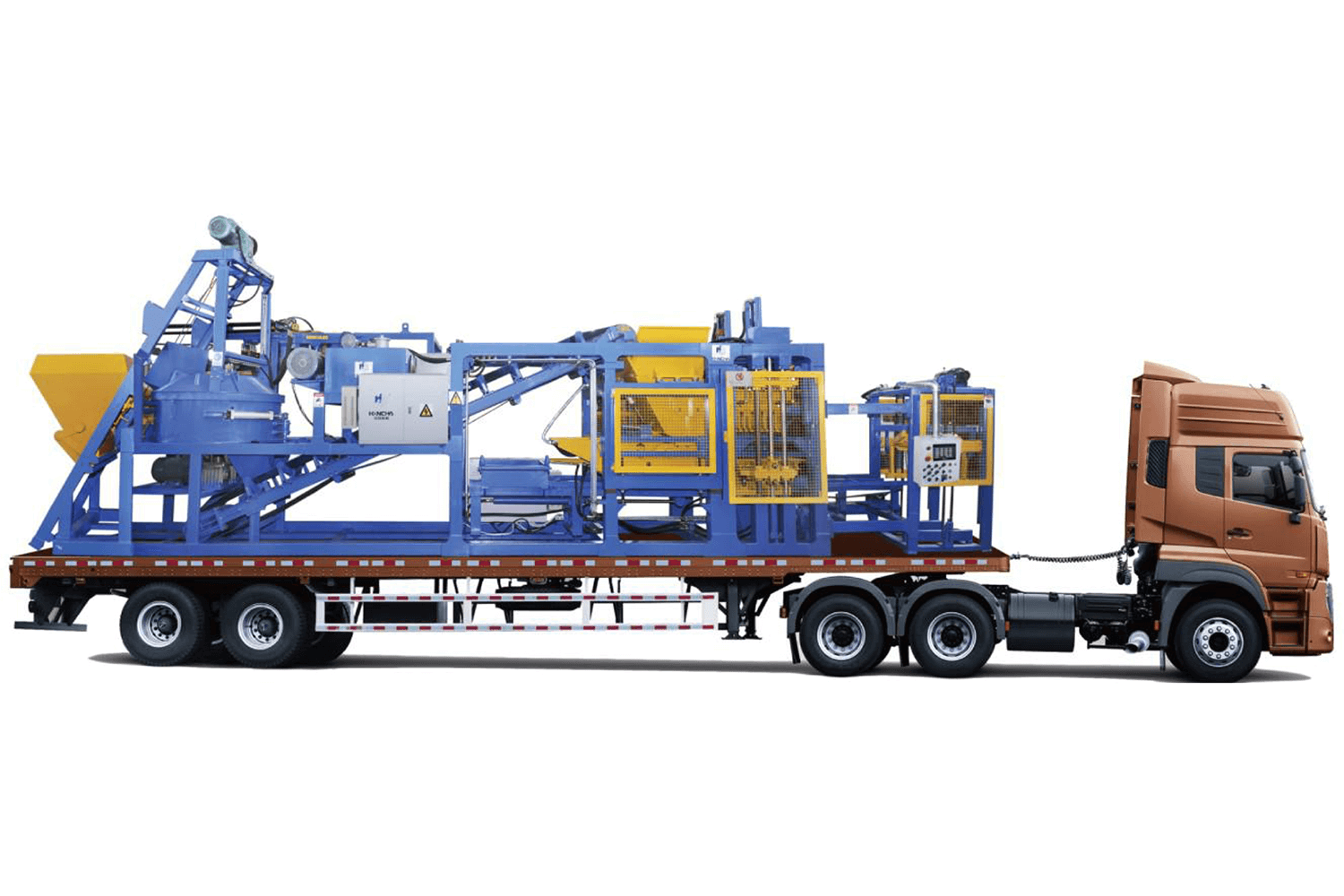

18 Years Factory Biggest Concrete Mixer – Hercules M block machine – Honcha

18 Years Factory Biggest Concrete Mixer – Hercules M block machine – Honcha Detail:

Hercules is your best choice for

-Economic

-Durability

-High Productivity

-High Quality

with wide range of products such as concrete blocks, pavers, kerbs, retaining wall units, planters and etc.

——Core Technology——

1.Smarter Factory &Easier Management

* High Precise Laser Scanning System

* Easy Production Date Management

* Automatic Warning Sign And Stop System For Wrong Products

* Real-time Production Process Monitoring Either By Mobile Or Computer.

2.Mechanical Parts

* Main Frame Consists Of 3 Moveable Parts, Easier For Maintenance

* Base Frame Is Made By 70mm Solid Steel Structure, Able To Stand Long-Time Strong Vibration

* 4 Synchronized Vibration Motor, More Efficient Vibration, Frequency Controlled

* Bolts and Nuts Design For All Spare Parts, User-Friendly For Maintenance.

* Automatic& Quick Mould Change Device(Within 3 Mins)

* Higher Block Height:Max.500mm

German Technical Programming

Over 100 product recipes provided

Easy operation-visualized touch screen

Precise frequency vibration

Control program-High capacity inverter

Remote control for trouble-shooting

Powerful Hydraulic System

Hydraulic pump with higher capacity(75kw)

High speed control by proportional valves

——Model detail——

Vibration table

Filling box

Mold clamp

Quick mold changer

——Model Specification——

| Hercules M Model Specification | |

| Main Dimension(L*W*H) | 4850*2150*3390mm |

| Useful Moulding Area(L*W*H) | 1280*850*40~500mm |

| Pallet Size(L*W*H) | 1400*900*40mm |

| Pressure Rating | 15Mpa |

| Vibration | 100~120KN |

| Vibration Frequency | 2900~3400r/min (adjustment) |

| Cycle Time | 15s |

| Power(total) | 90KW |

| Gross Weight | 15.8T |

★For reference only

——Simple Production Line——

| ITEM | MODEL | POWER |

| 01 Automatic Stacker | For Hercules M System | 7.5KW |

| 02 Block Sweeper | For Hercules M System | |

| 03 Block Conveying System | For Hercules M System | 2.2KW |

| 04 Hercules M Block Machine | EV Hercules M System | 90KW |

| 05 Dry Mix Conveyor | 8m | 2.2KW |

| 06 Pallets Conveying System | For Hercules M System | 4.5KW |

| 07 Bulk pallet feeder | For Hercules M System | |

| 08 Cement silo | 50T | |

| 09 JS1500 Enhanced Mixer | JS1500 | 48KW |

| 10 3-Compartments Batching Station | PL1600 III | 13KW |

| 11 Screw Conveyor | 12m | 7.5KW |

| 12 Cement Scale | 300KG | |

| 13 Water Scale | 100KG | |

| A Fork Lift (Optional) | 3T | |

| B Face Mix Section (Optional) | For Hercules M System |

★The above items can be reduced or added as needed. such as: cement silo(50-100T),screw conveyor, batching machine, automatic pallet feeder ,wheel loader, folk lift, air compressor.

—— Production Capacity——

| Hercules M | Prouduction Boards:1400*900 Production Area:1300*850 Stone Height:40~500mm | |||||

| Proudct | Size(mm) | Face mix | Pcs/cycle | Cycles/min | Prodcution/8h | Production cubic m/8h |

| Standard Brick | 240×115×53 | X | 60 | 4 | 115,200 | 169 |

| Hollow block | 400*200*200 | X | 12 | 3.5 | 20,160 | 322 |

| Hollow block | 390×190×190 | X | 12 | 3.5 | 20,160 | 284 |

| Hollow Brick | 240×115×90 | X | 30 | 3.5 | 50,400 | 125 |

| Paver | 225×112.5×60 | X | 30 | 4 | 57,600 | 87 |

| Paver | 200*100*60 | X | 42 | 4 | 80,640 | 97 |

| Paver | 200*100*60 | O | 42 | 3.5 | 70,560 | 85 |

★For Reference Only

★Other brick sizes not mentioned may provide drawings to inquire about specific production capacity.

Product detail pictures:

Related Product Guide:

Generally customer-oriented, and it's our ultimate goal for being not only the most trusted, trustable and honest provider, but also the partner for our customers for 18 Years Factory Biggest Concrete Mixer – Hercules M block machine – Honcha , The product will supply to all over the world, such as: Mexico , Australia , Monaco , Our company sticks to the principle of "high quality, reasonable price and timely delivery". We sincerely hope to establish good cooperative relationships with our new and old business partners from all parts of the world. We hope to work with you and serve you with our excellent goods and services. Welcome to join us!

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.

+86-13599204288

+86-13599204288