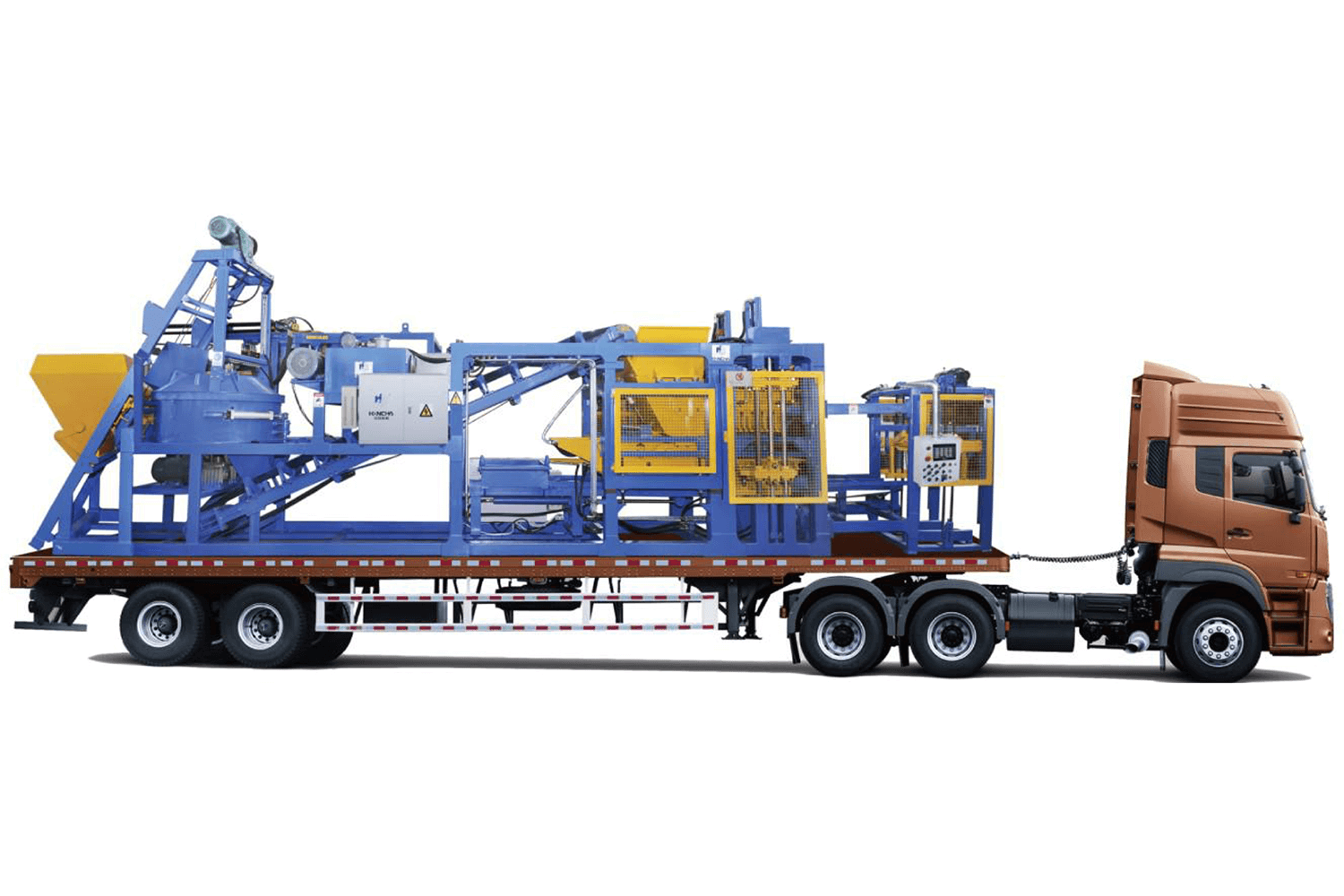

2019 China New Design Ceramic Brick Making Machine - Full Automatic Concrete Block Production Line – Honcha

2019 China New Design Ceramic Brick Making Machine - Full Automatic Concrete Block Production Line – Honcha Detail:

——Introduce——

Fully automatic line: wheel loader will put different aggregates in the Batching Station, it will measure them to the required weight and then combine with the cement from cement silo. All of the materials will then be sent to the mixer. After being mix evenly, the belt conveyer will convey the materials to the Block Making Machine. The finished blocks will be transferred to the Automatic Elevator. Then the finger car will take all pallets of blocks to the curing chamber for curing. The finger car will take other cured blocks to the Automatic Lowerator. And pallet tumbler can get rid of the pallets one by one and then Automatic cuber will take the blocks and stack them to a pile, then the fork clamp can take the finished blocks to the yard for sales.

——Component——

1 Batching and Mixing Plant

The batching and mixing system consists of a multi-component batching station which automatically weighs and conveys the aggregate to the compulsory mixer. The cement is transported from the cement silo using a screw conveyor and automatically weighed at the mixer. Once the mixer has completed its cycle the concrete will be transported using our overhead skip system to the fully automatic block machine system.

2、Block machine

The concrete is pushed into place by a feeder box and spread evenly into the bottom female mould. The top male mould is then inserted into the bottom mould and the use synchronized table vibration from both moulds to compact the concrete into the desired block. The machine can have a fully automatic face mix section added to allow the production of colored pavers.

Optional block machine models: Hercules M, Hercules L, Hercules XL.

3、Pallet Elevator

The fresh blocks are cleaned to make sure they are all the same height and then transported to the elevator system. It can be manufactured to be from nine to twelve levels high with two pallets per level of bamboo or steel loader with the fresh blocks.

4、Finger Car System (Mother and Son Car)

The finger car system is built to the same number of levels as the elevator system and is designed to withstand the strain of unloading a max capacity elevator of blocks or pavers. It will transport and unload the cargo into the curing chamber for a pre determined time based on the factories geographic location. The blocks will be unloaded and transported to the lowerator.

5、Pallet Lowerator

When the pallets have been fully loaded into the lowerator every level is automatically unloaded on to the pallet return system and aligned ready for the cubing system.

6、Automatic Gantry Type Block Cubing System

The cubing system will collect the blocks or pavers from two pallets at a time and cross stack them onto the exit conveyor. It is equipped with four rubber covered clamping arms and hydraulically operated with 360 degree horizontal movement.

——Full Automatic Production Line——

| Full Automatic Concrete Block Production Line: Items | ||

| 1 Automatic Batching Station | 2 Compulsory Mixer | 3 Cement Silo |

| 4 Screw Conveyor | 5 Cement Scale | 6 Belt Conveyor |

| 7 Pallets Conveying System | 8 Concrete Block Machine | 9 Blocks Conveying System |

| 10 Block Sweeper | 11 Elevator | 12 Lowerator |

| 13 Pallet Tumbler | 14 Automatic Gantry Type Cuber | 15 Finger Car System |

| 16 Central Control Room | 17 Hydraulic Station | 18 Wheel Loader |

| 19 Fork lift | 20 Curing Chamber | |

Wrapping machine

Pallet turn over

Curing room

Dry side

—— Production Capacity——

★Other brick sizes not mentioned may provide drawings to inquire about specific production capacity.

| Production capacity | ||||||

| Hercules M | Prouduction Boards:1400*900 Production Area:1300*850 Stone Height:40~500mm | |||||

| Proudct | Size(mm) | Face mix | Pcs/cycle | Cycles/min | Prodcution/8h | Production cubic m/8h |

| Standard Brick | 240×115×53 | X | 60 | 4 | 115,200 | 169 |

| Hollow block | 400*200*200 | X | 12 | 3.5 | 20,160 | 322 |

| Hollow block | 390×190×190 | X | 12 | 3.5 | 20,160 | 284 |

| Hollow Brick | 240×115×90 | X | 30 | 3.5 | 50,400 | 125 |

| Paver | 225×112.5×60 | X | 30 | 4 | 57,600 | 87 |

| Paver | 200*100*60 | X | 42 | 4 | 80,640 | 97 |

| Paver | 200*100*60 | O | 42 | 3.5 | 70,560 | 85 |

| Hercules L | Prouduction Boards:1400*1100 Production Area:1300*1050 Stone Height:40~500mm | |||||

| Proudct | Size(mm) | Face mix | Pcs/cycle | Cycles/min | Prodcution/8h | Production cubic m/8h |

| Standard Brick | 240×115×53 | X | 80 | 4 | 153,600 | 225 |

| Hollow block | 400*200*200 | X | 15 | 3.5 | 25,200 | 403 |

| Hollow block | 390×190×190 | X | 15 | 4 | 14,400 | 203 |

| Hollow Brick | 240×115×90 | X | 40 | 4 | 76,800 | 191 |

| Paver | 225×112.5×60 | X | 40 | 4 | 76,800 | 116 |

| Paver | 200*100*60 | X | 54 | 4 | 103,680 | 124 |

| Paver | 200*100*60 | O | 54 | 3.5 | 90,720 | 109 |

| Hercules XL | Prouduction Boards:1400*1400 Production Area:1300*1350 Stone Height:40~500mm | |||||

| Proudct | Size(mm) | Face mix | Pcs/cycle | Cycles/min | Prodcution/8h | Production cubic m/8h |

| Standard Brick | 240×115×53 | X | 115 | 4 | 220,800 | 323 |

| Hollow block | 400*200*200 | X | 18 | 3.5 | 30,240 | 484 |

| Hollow block | 390×190×190 | X | 18 | 4 | 34,560 | 487 |

| Hollow Brick | 240×115×90 | X | 50 | 4 | 96,000 | 239 |

| Paver | 225×112.5×60 | X | 50 | 4 | 96,000 | 146 |

| Paver | 200*100*60 | X | 60 | 4 | 115,200 | 138 |

| Paver | 200*100*60 | O | 60 | 3.5 | 100,800 | 121 |

Product detail pictures:

Related Product Guide:

We insist over the principle of development of 'High top quality, Performance, Sincerity and Down-to-earth working approach' to supply you with exceptional services of processing for 2019 China New Design Ceramic Brick Making Machine - Full Automatic Concrete Block Production Line – Honcha , The product will supply to all over the world, such as: Curacao , Swedish , British , With the development and enlargement of mass clients abroad, now we've set up cooperative relationships with many major brands. We've our own factory and also have many reliable and well-cooperated factories in the field. Adhering to the "quality first, customer first, We are provideing high-quality, low-cost items and first-class service to customers. We sincerely hope to establish business relationship with customers from all over the world on the basis of quality, mutually benefit. We welcome OEM projects and designs.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.

+86-13599204288

+86-13599204288