2019 Latest Design Automatic Block Moulding Machine - QT9-15 block machine – Honcha

2019 Latest Design Automatic Block Moulding Machine - QT9-15 block machine – Honcha Detail:

——Features——

1.Newly developed screen feeder with agitators to ensure even and fast material feeding into the mould box. The claws inside the feeder are agitating continously to reduce the stickiness of dry mix before feeding.

2. Improved synchronous table vibration system effectively transmits the maximum vibration to the mould box, thus greatly increase block quality and at the same time extend the mould working life.

3. The new technique of curing will greatly save the investment costs i.e. 75% less number of pallets, 60% less plant shed area, only need 800㎡ stocking yard,60% less labour, saving 20 days cash flow.

4. Electric adjustment can be made on the lifting mechanism of platform and this is convenient and quick to adjust the height of different products.

——Model Specification——

| QT9-15 Model Specification | |

| Main Dimension(L*W*H) | 3120*2020*2700mm |

| Useful Moulding Area(L*W*H) | 1280*600*40-200mm |

| Pallet Size(L*W*H) | 1380*680*25mm |

| Pressure Rating | 8-15Mpa |

| Vibration | 60-90KN |

| Vibration Frequency | 2800-4800r/min (adjustment) |

| Cycle Time | 15-25s |

| Power(total) | 46.2KW |

| Gross Weight | 10.5T |

★For reference only

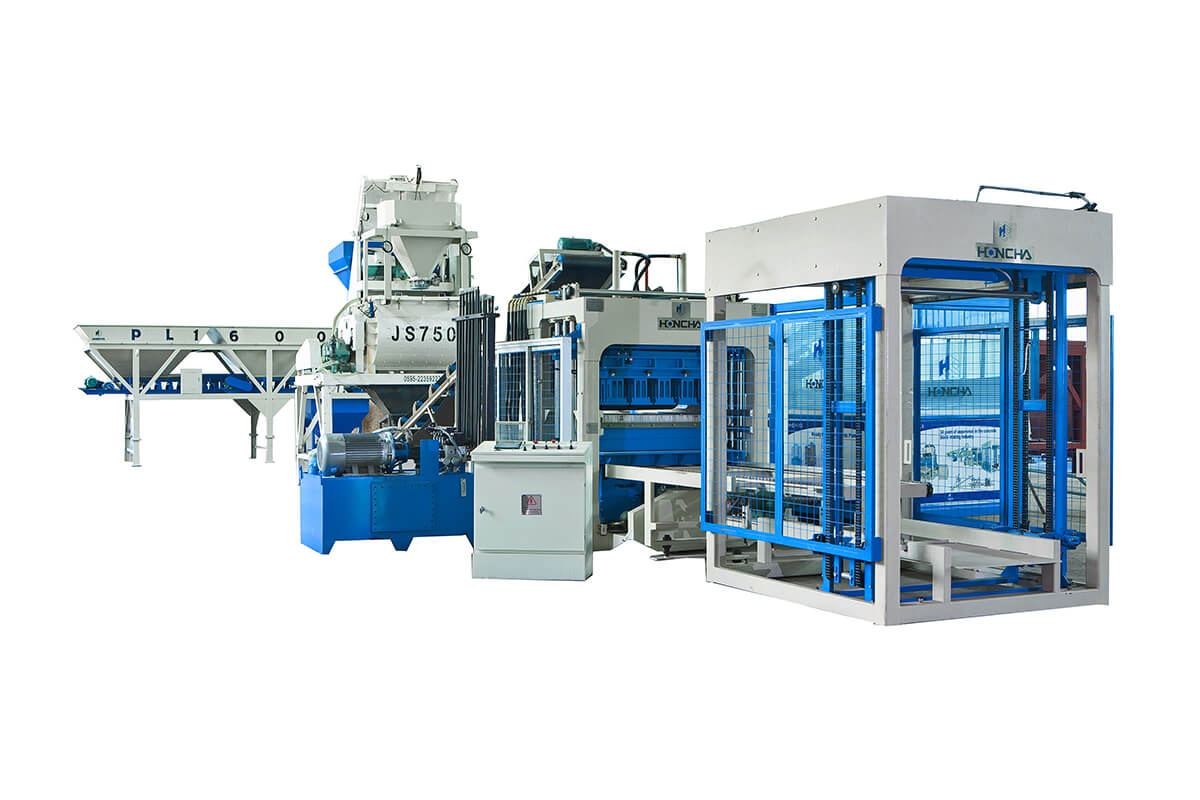

——Simple Production Line——

| ITEM | MODEL | POWER |

| 01 3-Compartments Batching Station | PL1600 III | 13KW |

| 02 Belt Conveyor | 6.1m | 2.2KW |

| 03 Cement silo | 50T | |

| 04 Water Scale | 100KG | |

| 05 Cement Scale | 300KG | |

| 06 Screw Conveyor | 6.7m | 7.5KW |

| 07 Enhanced Mixer | JS750 | 38.6KW |

| 08 Dry Mix Conveyor | 8m | 2.2KW |

| 09 Pallets Conveying System | For QT9-15 System | 1.5KW |

| 10 QT9-15 Block Machine | QT9-15 System | 46.2KW |

| 11 Block Conveying System | For QT9-15 System | 1.5KW |

| 12 Automatic Stacker | For QT9-15 System | 3.7KW |

| A Face Mix Section (Optional) | For QT9-15 System | |

| B Block Sweeper System(Optional) | For QT9-15 System |

★The above items can be reduced or added as needed. such as: cement silo(50-100T),screw conveyor, batching machine, automatic pallet feeder ,wheel loader, folk lift, air compressor.

—— Production Capacity——

★Other brick sizes not mentioned may provide drawings to inquire about specific production capacity.

Product detail pictures:

Related Product Guide:

The pretty loaded projects management experiences and one to a person support model make the high importance of business enterprise communication and our easy understanding of your expectations for 2019 Latest Design Automatic Block Moulding Machine - QT9-15 block machine – Honcha , The product will supply to all over the world, such as: New York , UAE , Greenland , In the future, we promise to keep offer the high quality and more cost-effective products, the more efficient after sales service to our all customers all over the world for the common development and the higher benefit.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.

+86-13599204288

+86-13599204288