Best Price on Batching Plant Procedure - Crushing sand washing equipment – Honcha

Best Price on Batching Plant Procedure - Crushing sand washing equipment – Honcha Detail:

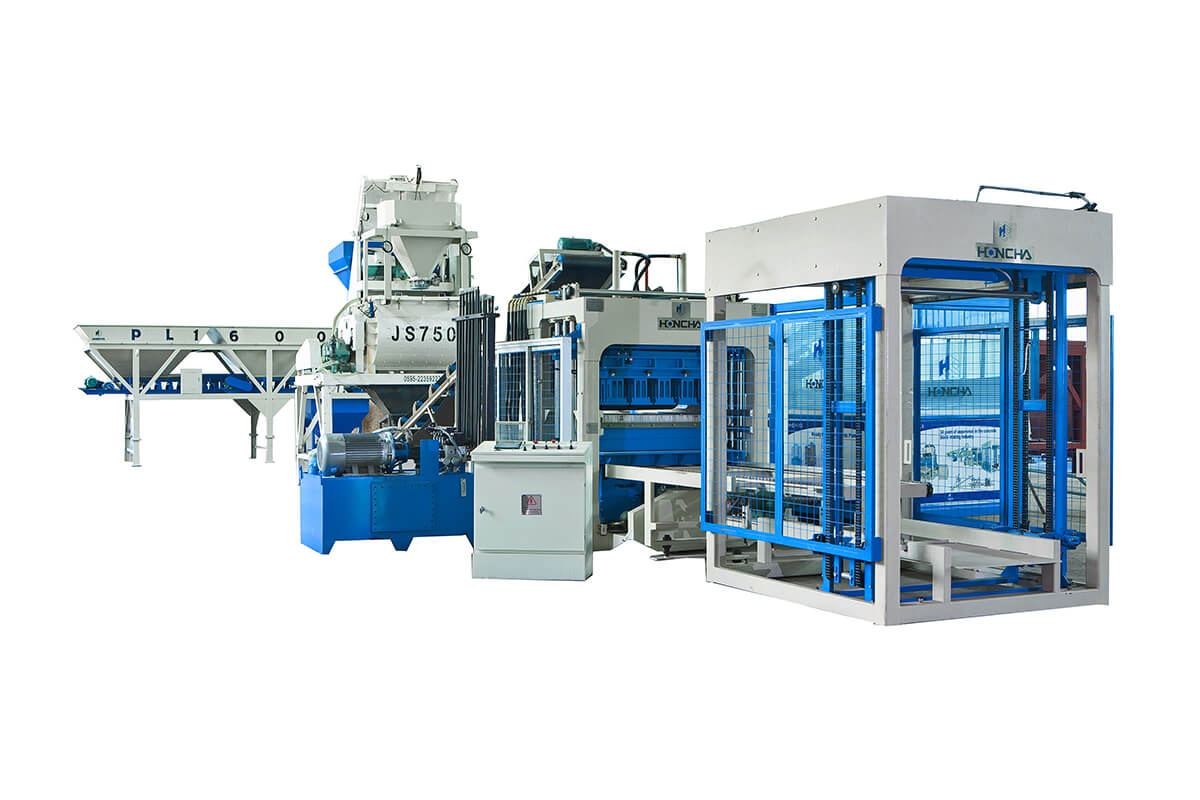

Honcha concrete crushing production line is based on the results of the latest R&D and design of China’s working conditions. It is mainly used in artificial sand production equipment such as broken solid building waste, river pebbles, mountain rocks, ore tailings, and stone chips, which can protect resources and can be turned into waste for profit. Both environmental protection and economic benefits can be obtained from the use of waste. It is a high-performance sand breaking equipment in China. The equipment provides high-quality sand and stone aggregate for highways, high-speed rail, high-rise buildings, municipalities, hydropower dams, and concrete mixing stations. It is the preferred equipment for artificial sand and river stone shaping.

——Technical Specification——

| Technical Specification | |||||||

| Technical parameters of vibration feeding machine | |||||||

| Model No. | Funnel Dimension(mm) | Maximum Feeding(mm) | Capacity(t/h) | Power(kw) | Weight(kg) | Outlet Dimension(mm) | |

| HCM850X3000 | 850X3000 | 400 | 80-120 | 7.5 | 3895 | 3110X1800X1600 | |

| HCM960X3800 | 960X3800 | 500 | 120-210 | 11 | 3980 | 3850X1950X1630 | |

| HCM1100X4200 | 1100X4200 | 580 | 200-430 | 15 | 4170 | 4400X2050X1060 | |

| HCM1300X4900 | 1300X4900 | 650 | 450-600 | 22 | 5200 | 5200X2350X1750 | |

| Jaw Crusher | |||||||

| Model No. | Feeding port(mm) | Maximum Feeding(mm) | Adjustable range(mm) | Maximum Feeding(mm) | Power(kw) | Outlet Dimension(mm) | Weight(kg) |

| HCR500X750 | 500X750 | 425 | 50-100 | 40-110 | 45-55 | 2035X1921X2000 | 12 |

| HCR600X900 | 600X900 | 480 | 65-160 | 90-180 | 55-75 | 2290X2206X2370 | 17 |

| HCR750X1060 | 750X1060 | 630 | 80-140 | 110-320 | 90-110 | 2655X2303X3110 | 29 |

| HCR900X1200 | 900X1200 | 750 | 95-165 | 220-450 | 110-132 | 3800X3166X3045 | 52 |

| Counterattack Crusher | |||||||

| Model No. | Feeding port(mm) | Maximum Feeding(mm) | Capacity(t/h) | Power(kw) | Weight(kg) | Specification(kg) | |

| EX-1007 | 400X730 | <250 | 15-60 | 37-55 | 9.5 | Ø1000X700 | |

| EX-1010 | 400X1080 | <300 | 50-90 | 55-75 | 14 | Ø1000X1050 | |

| EX-1210 | 400X1080 | <300 | 70-130 | 110-132 | 17 | Ø1250X1050 | |

| EX-1214 | 400X1430 | <300 | 90-180 | 132-160 | 22 | Ø1250X1400 | |

| Vibration sieve | |||||||

| Model No. | Sieve specification(mm) | Layer No. | Filter size(mm) | Feeding size(mm) | Capacity(t/h) | Vibration frequency(r/min) | Power(kw) |

| ZDS1237 | 1200X3700 | 1 | 4-50 | ≤200 | 10-80 | 960 | 5.5X2 |

| 2ZDS1237 | 1200X3700 | 2 | 4-50 | ≤200 | 10-80 | 960 | 5.5X2 |

| 2YK1548 | 4800X1500 | 2 | 3-100 | ≤400 | 30-275 | 870 | 15 |

| 3YK1548 | 4800X1500 | 3 | 3-100 | ≤400 | 30-275 | 870 | 15 |

| 2YK1848 | 4800X1800 | 2 | 3-100 | ≤400 | 56-330 | 870 | 18.5 |

| 3YK1848 | 4800X1800 | 3 | 3-100 | ≤400 | 56-330 | 870 | 18.5 |

| 2YK1860 | 6000X1800 | 2 | 3-100 | ≤400 | 65-586 | 870 | 22 |

| 3YK1860 | 6000X1800 | 2 | 3-100 | ≤400 | 65-586 | 870 | 22-30 |

| Technical parameters of the washing machine | |||||||

| Model No. | Impeller specification(mm) | Impeller speed(mm) | Maximum feeding(mm) | Type of reducer | Capacity(t/h) | Outlet Dimension(mm) | Power(kw) |

| XSD2610 | 2600X1000 | 1.178 | ≤10 | ZQ50-50-I-Z | 20-50 | 3255X1982X2690 | 5.5 |

| XSD2816 | 2800X1600 | 1.177 | ≤10 | ZQ50-50-I-Z | 30-60 | 3540X3000X2800 | 7.5-11 |

| XSD3016 | 3000X1600 | 1.179 | ≤10 | ZQ50-50-I-Z | 50-120 | 3845X3000X3080 | 11-15 |

Product detail pictures:

Related Product Guide:

Innovation, excellent and reliability are the core values of our business. These principles today extra than ever form the basis of our success as an internationally active mid-size company for Best Price on Batching Plant Procedure - Crushing sand washing equipment – Honcha , The product will supply to all over the world, such as: Roman , Bahrain , United Arab Emirates , Our stock have valued 8 million dollar , you can find the competitive parts within short delivery time. Our company is not only your partner in business, but also our company is your assistant in the coming corporation.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.

+86-13599204288

+86-13599204288