factory low price Concrete Mixer ruck - U15-15 Pallet-free block machine – Honcha

factory low price Concrete Mixer ruck - U15-15 Pallet-free block machine – Honcha Detail:

U15-15 pallet-free block making machine automatic production line is a wall brick and paver forming equipment independently developed by our company. The effective production area can reach 1.22 *1.22 ㎡; the volume melting weight of products can reach 2400 KG/M3 and the water absorption rate can be less than 6%. The weight error of products is only (+1.5%) and the strength error can reach (+10%); the height error of products can be controlled to (+0.2 mm).Automatic stacking immediately after moulding, pallet free, no auxiliary equipments, consumables-free. Per shift capacity of 120,000 pieces standard bricks containing automatic packing , only need three workers. And later loading and unloading also need no manual!

Honcha Block Machine belongs to the general equipment of concrete block. By changing moulds, various concrete blocks can be produced, such as new insulation bricks, hollow blocks, multi-row perforated bricks, solid bricks, etc., various road bricks, such as interlocking bricks, permeable bricks, roadside stones, and various kinds of concrete block used for parks, airports, wharfs and other places such as hydraulic bricks, retaining bricks, flowerpot bricks, fence bricks, etc.

The equipment is suitable for manufacturing high-quality, high-strength concrete or fly ash blocks, and is one of the most advanced model in China.

——Features——

1.Large forming area: the effective forming area can be 1.22 m *1.22 m.

2.High production capacity of single machine: 15~18 seconds can complete a molding cycle, each time can produce 15pcs blocks with size 390*190*190mm, the production of standard brick can reach 15,000 pcs per hour.

3.Pallet-free Production: immediately stacking after molding, without hundreds of thousands of pallets input.

4.High density molding: melting weight can reach 2.3t per cubic meter, water absorption rate can be less than 8%, high density allows less cement to make high strength products, high mud content materials can also produce high quality products

5.Save a lot of labor: molding immediately stacking, no need for finished products maintenance, transport, stacking and other support equipment.

6.Mobile module: the equipment is divided into several modules, which can be quickly installed on site and can be manufactured on the ground and can be transferred quickly with the project and market without the construction cycle.

7.Can do project operation for users, responsible for: quality management, capacity assurance, cost control, equipment maintenance, formulation process.

——Model Specification——

| U15-15 Model Specification | |

| Main Dimension(L*W*H) | 8640*4350*3650mm |

| Useful Moulding Area(L*W*H) | 1220*1220*60~200mm |

| Pallet Size(L*W*H) | 1280*1280*88mm |

| Pressure Rating | 12~25Mpa |

| Vibration | 120~210KN |

| Vibration Frequency | 3200~4000r/min (adjustment) |

| Cycle Time | 15s |

| Power(total) | 100KW |

| Gross Weight | 70T |

v:* {behavior:url(#default#VML);}

o:* {behavior:url(#default#VML);}

x:* {behavior:url(#default#VML);}

.shape {behavior:url(#default#VML);}

★For reference only

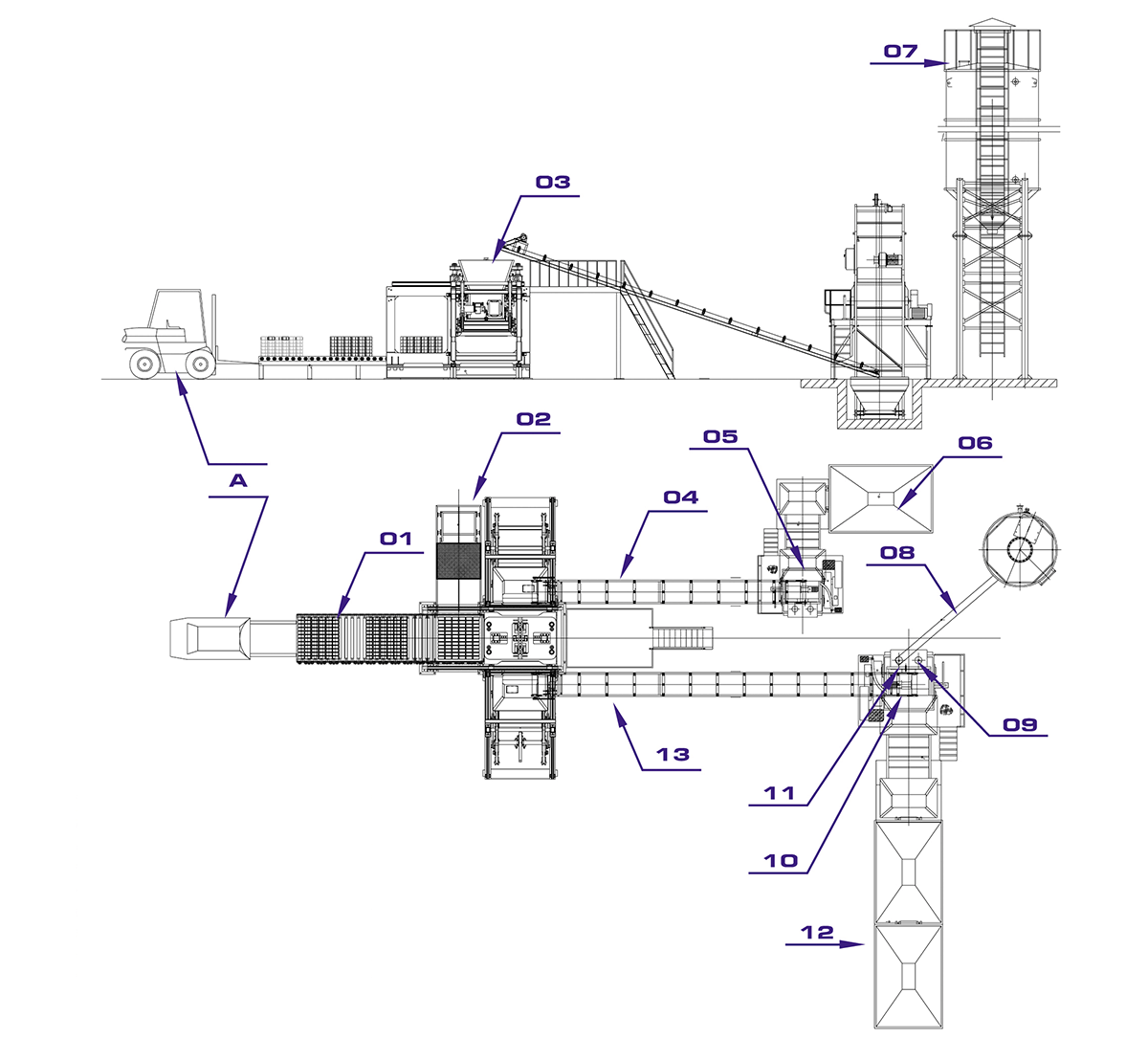

——Simple Production Line——

|

ITEM |

|

| 01 Block Conveying System | 08 Screw Conveyor |

| 02 Pallets Conveying System | 09 Water Scale |

| 03 U15-15 Pallet-free Block Machine | 10 MP1500/2000 Face Material Mixer |

| 04 Face Material Conveyor System | 11 Cement Scale |

| 05 MP330 Face Material Mixer | 12 2-Compartments Base Material Batching |

| 06 1-Compartments Face Material Batching Station | 13 Base Material Conveyor System |

| 07 Cement silo | A Fork Lift (Optional) |

★The above items can be reduced or added as needed. such as: cement silo(50-100T),screw conveyor, batching machine, automatic pallet feeder ,wheel loader, folk lift, air compressor.

Automatic packing machine

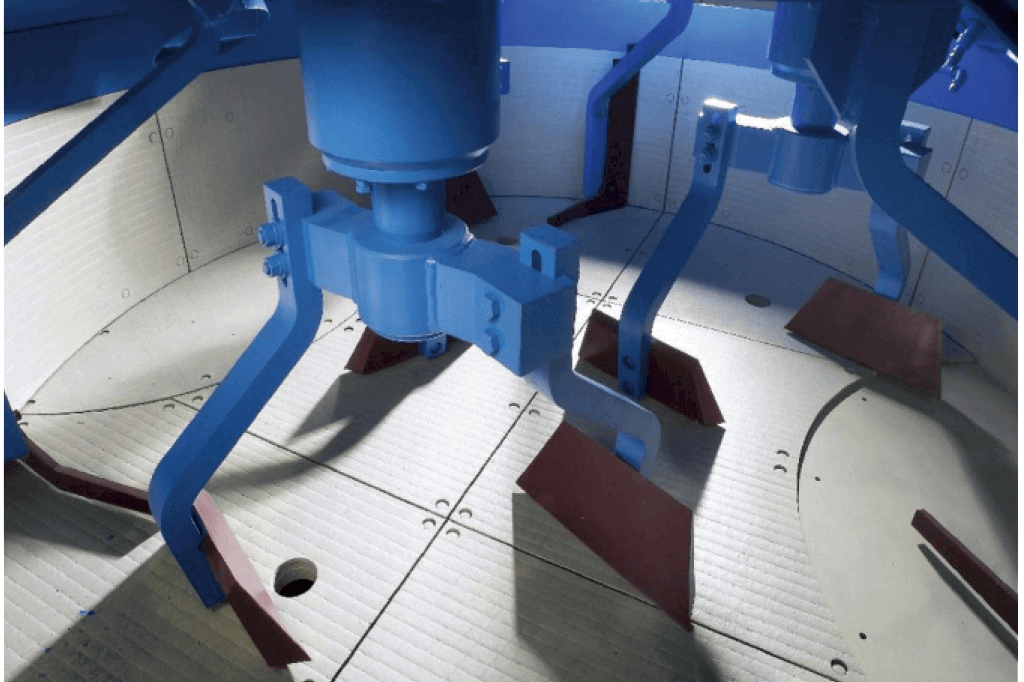

Planettary mixer

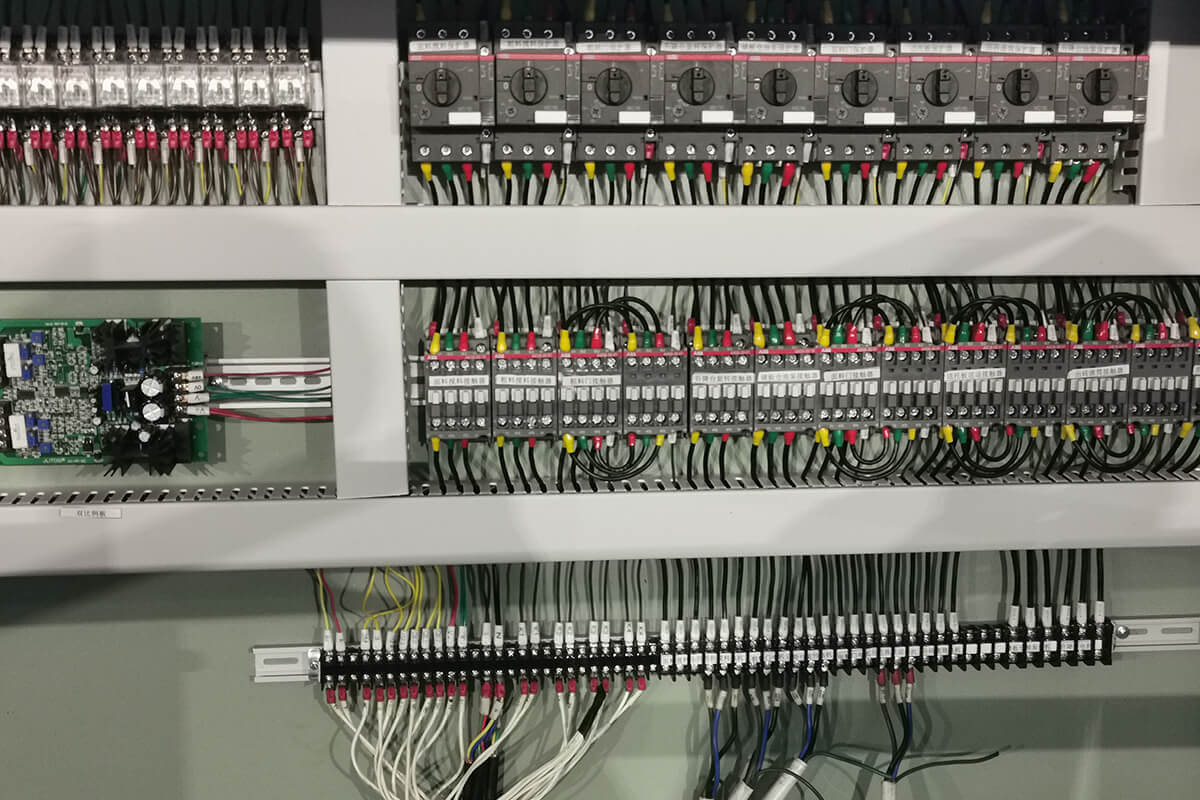

Control panel

Batching machine

—— Production Capacity——

★Other brick sizes not mentioned may provide drawings to inquire about specific production capacity.

Product detail pictures:

Related Product Guide:

We have a highly efficient team to deal with inquiries from customers. Our goal is "100% customer satisfaction by our product quality, price & our team service" and enjoy a good reputation among clients. With many factories, we can provide a wide range of factory low price Concrete Mixer ruck - U15-15 Pallet-free block machine – Honcha , The product will supply to all over the world, such as: Algeria, Belize, Egypt, Our company has already have pass the ISO standard and we're fully respect our customer 's patents and copyrights. If the customer provides their own designs, We will guarantee that they will likely be the only one can have that merchandise. We hoping that with our good products can bring our customers a great fortune.

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!

+86-13599204288

+86-13599204288