High Quality for Baking Free Concrete Block Machine - Simple Automatic Concrete Block Production Line – Honcha

High Quality for Baking Free Concrete Block Machine - Simple Automatic Concrete Block Production Line – Honcha Detail:

——Features——

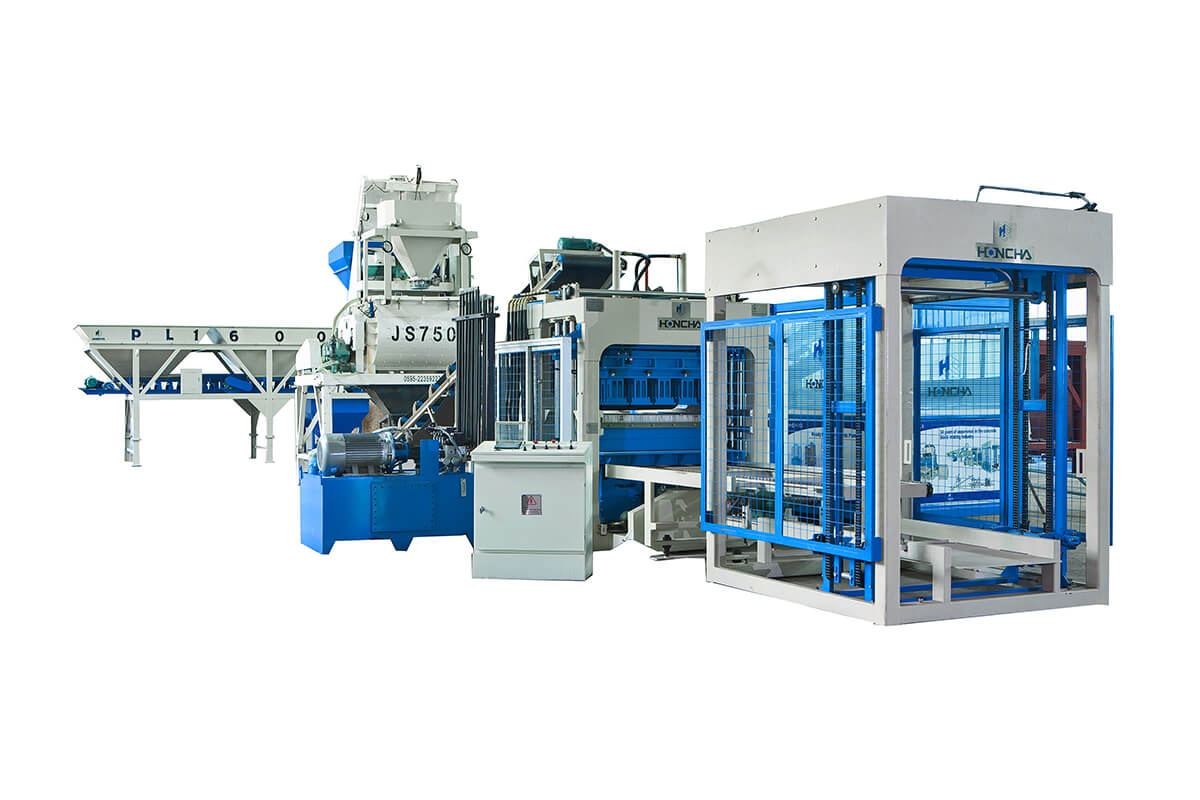

Simple production line: Putting different aggregates in the Batching Station, it will measure them to the required weight and then combine with the cement from cement silo. All of the materials will then be sent to the mixer. After being mix evenly, the belt conveyer will convey the materials to the Block Making Machine. The finished blocks after being cleaned by the block sweeper will be transferred to the stacker. The folk lift or two workers can take the blocks to the yard for natural curing.

——Component——

1 Batching and Mixing Plant

The batching and mixing system consists of a multi-component batching station which automatically weighs and conveys the aggregate to the compulsory mixer. The cement is transported from the cement silo using a screw conveyor and automatically weighed at the mixer. Once the mixer has completed its cycle the concrete will be transported using our overhead skip system to the fully automatic block machine system.

2、 Block machine

The concrete is pushed into place by a feeder box and spread evenly into the bottom female mould. The top male mould is then inserted into the bottom mould and the use synchronized table vibration from both moulds to compact the concrete into the desired block. The machine can have a fully automatic face mix section added to allow the production of colored pavers.

Optional block machine models:QT6-15,QT8-15,QT9-15,QT10-15,QT12-15.

3、Stacker

The fresh blocks are cleaned to make sure they are all the same height and then transported to the stacker. Then the fork lift will take all pallets of blocks to the yard for natural curing.

——Simple Automatic Production Line——

|

Simple Automatic Concrete Block Production Line: Items |

||

| 1 Automatic Batching Station | 2 Cement Silo | 3 Screw Conveyor |

| 4 Cement Scale | 5 Compulsory Mixer | 6 Belt Conveyor |

| 7 Pallet Conveying System | 8 Concrete Block Machine | 9 Face Mix Section |

| 10 Blocks Conveying System | 11 Automatic Stacker | 12 Fork Lift |

| 13 Wheel Loader | ||

Automatic batching station

Compulsory mixer

—— Production Capacity——

★Other brick sizes not mentioned may provide drawings to inquire about specific production capacity.

Product detail pictures:

Related Product Guide:

During the past few years, our business absorbed and digested state-of-the-art technologies the two at home and abroad. Meanwhile, our firm staffs a group of experts devoted to your development of High Quality for Baking Free Concrete Block Machine - Simple Automatic Concrete Block Production Line – Honcha , The product will supply to all over the world, such as: Jeddah , Algeria , Venezuela , Now, with the development of internet, and the trend of internationalization, we've got decided to extend business to overseas market. With the propose of bringing more profits to oversea customers by providing directly abroad. So we have changed our mind, from home to abroad, hope to give our customers more profit, and looking forward to more chance to make business.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.

+86-13599204288

+86-13599204288