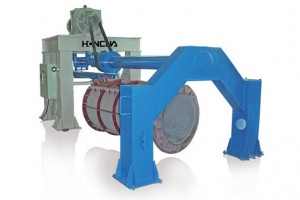

Pipe making machine

——Main function——

HCP 2000 concrete cement pipe making machine is mixing raw materials such as cement, sand, water and so on, evenly spreading concrete into cylinder wall under the action of centrifugal force in the main machine, forming concrete chamber under the action of centrifugal, roll-pressing and vibration, so as to achieve the paving effect. It can produce various kinds of overhanging rollers, such as drainage pipe flat, enterprise, steel socket, double socket, socket, PH pipe, Danish pipe and so on. It can also produce various types of units according to user's requirements, and make concrete cement pipes with different inner diameters by changing different moulds. Concrete pipes can reach the required strength through normal maintenance and steam maintenance. It is a pipe-making machine with simple operation and reliable product quality.

——Mold Specifications——

| Mold Specifications for Cement Piping Machines | |||||||||

| Length(mm) | 2000 | ||||||||

| Inside diameter(mm) | 300 | 400 | 500 | 600 | 700 | 800 | 1000 | 1200 | 1500 |

| Out diameter(mm) | 370 | 480 | 590 | 700 | 820 | 930 | 1150 | 1380 | 1730 |

——Technical Parameters——

| Model No. | HCP800 | HCP1200 | HCP1650 |

| Pipe diameter(mm) | 300-800 | 800-1200 | 1200-1650 |

| Suspension axis diameter (mm) | 127 | 216 | 273 |

| Pipe length(mm) | 2000 | 2000 | 2000 |

| Motor type | YCT225-4B | Y225S-4 | YCT355-4A |

| Motor power (kw) | 15 | 37 | 55 |

| cantilever speed(r/m) | 62-618 | 132-1320 | 72-727 |

| Whole machine dimension(mm) | 4100X2350X1600 | 4920X2020X2700 | 4550X3500X2500 |

+86-13599204288

+86-13599204288