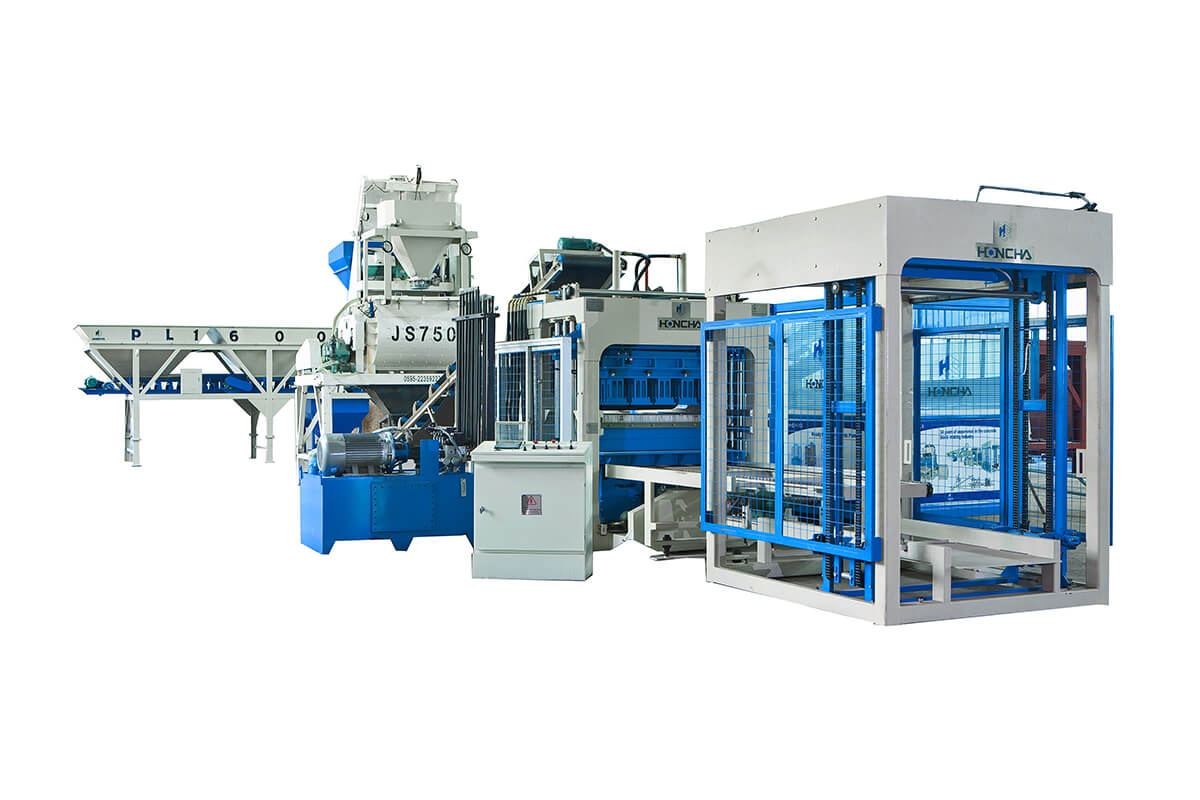

Renewable Design for Interlock Brick Machine - QT12-15 block machine – Honcha

Renewable Design for Interlock Brick Machine - QT12-15 block machine – Honcha Detail:

——Features——

1.Newly developed screen feeder with agitators to ensure even and fast material feeding into the mould box. The claws inside the feeder are agitating continously to reduce the stickiness of dry mix before feeding.

2. Innovative synchronous table vibration system double the useful molding area, greatly increase block quality and capacity, at the same time extend the mould working life.

3.Genuine Germany imported Bosch Air Squeeze Buds for noise and vibration absorption.

——Model Specification——

|

QT12-15 Model Specification |

|

| Main Dimension(L*W*H) | 3200*2020*2750mm |

| Useful Moulding Area(L*W*H) | 1280*850*40-200mm |

| Pallet Size(L*W*H) | 1380*880*30mm |

| Pressure Rating | 8-15Mpa |

| Vibration | 80-120KN |

| Vibration Frequency | 3000-3800r/min (adjustment) |

| Cycle Time | 15-25s |

| Power(total) | 54.2KW |

| Gross Weight | 12.6T |

★For reference only

——Simple Production Line——

|

ITEM |

MODEL |

POWER |

| 01 3-Compartments Batching Station | PL1600 III | 13KW |

| 02 Belt Conveyor | 6.1m | 2.2KW |

| 03 Cement silo | 50T | |

| 04 Water Scale | 100KG | |

| 05 Cement Scale | 300KG | |

| 06 Screw Conveyor | 6.7m | 7.5KW |

| 07 Enhanced Mixer | JS1000 | 51KW |

| 08 Dry Mix Conveyor | 8m | 2.2KW |

| 09 Pallets Conveying System | For QT12-15 System | 1.5KW |

| 10 QT12-15 Block Machine | QT12-15 System | 54.2KW |

| 11 Block Conveying System | For QT12-15 System | 1.5KW |

| 12 Automatic Stacker | For QT12-15 System | 3.7KW |

| A Face Mix Section (Optional) | For QT12-15 System | |

| B Block Sweeper System(Optional) | For QT12-15 System |

★The above items can be reduced or added as needed. such as: cement silo(50-100T),screw conveyor, batching machine, automatic pallet feeder ,wheel loader, folk lift, air compressor.

—— Production Capacity——

★Other brick sizes not mentioned may provide drawings to inquire about specific production capacity.

Product detail pictures:

Related Product Guide:

In the past few years, our company absorbed and digested advanced technologies both at home and abroad. Meanwhile, our company staffs a team of experts devoted to the development of Renewable Design for Interlock Brick Machine - QT12-15 block machine – Honcha , The product will supply to all over the world, such as: Sacramento , Mauritius , Poland , Our products are sold to the Middle East, Southeast Asia, Africa, Europe, America and other regions, and are favorably appraised by clients. To benefit from our strong OEM/ODM capabilities and considerate services, please contact us today. We will sincerely create and share success with all clients.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.

+86-13599204288

+86-13599204288